Fiber Reinforced Plastic or FRP is also known as fiber Reinforced Polymer. FRP is a composite material that is used extensively to make several products. FRP is made using a polymer matrix which is reinforced carefully with fibers. However, it is not used to reinforce any fiber, but only glass fibers. Mostly, it is reinforced with fiberglass, and thus, the material is known as FRP. However, at times, even other materials, like wood, paper, or some other chemical-based Fiber Reinforced Plastic or FRP is also known as fiber Reinforced Polymer. FRP is a composite material that is used extensively to make several products. are also reinforced. Vinyl ester, epoxy as well as polyester thermosetting are some of the polymers which are used for the reinforcement. And, after the complete process, FRP is used to make several other products, like FRP cable trays, gratings, etc. In this article, we will talk about a few of the top qualities of FRP.

Listed below are a few of the best characteristics of FRP that make it a top choice of the industry:

Comparatively light in weight

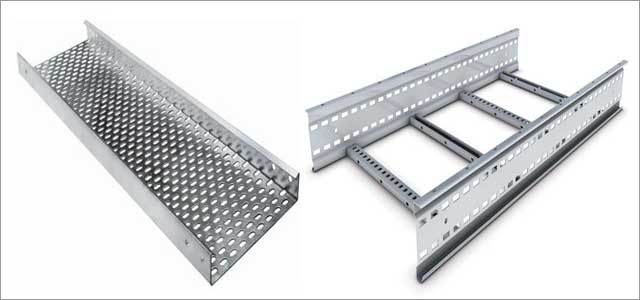

FRP is used extensively because it is quick to install. Less installation time is one of the top characteristics that make FRP several other materials. Being a lightweight material it is used to make FRP cable trays, gratings, and plenty of other products. FRP is light in weight, it is almost 8 times less in weight than reinforced concrete. What does this mean? Well, this implies that installing products made using FRP could be installed easily with less labor. Also, less effort is required to install FRP products, like FRP gratings and FRP cable trays.

Ease of installation and maintenance

FRP products are less in weight so easy to transport and install. Additionally, you would require less equipment and tools to install FRP products. That’s not it, you would also need lesser labor and work when it comes to the removal of the FRP products. You won’t have to spend a lot of time or effort in the maintenance of FRP products. FRP products are easy to maintain and the wear and tear are also quite smooth.

Variety of applications

Fiberglass Reinforced Plastic is becoming more and more popular day by day. Also, in the coming future, FRP would be used more. At present, it is also used in several industries, like construction, marine, aerospace, automotive, and a wide range of other industries. FRP is a top choice of the market. It is used to make several products; and it is also used to make various designs that require lighter materials. Some of the top FRP products are FRP Ladders India and FRP gratings, but that’s not enough, FRP is used to make several other products.

Read Also: Amaze Your Parents With Perfect Marriage Anniversary Gifts

Listed above are only a few of the top qualities of FRP. FRP is a reinforced plastic, therefore, it is made after a certain process. However, as the demand for FRP products is increasing, therefore, more and more companies are manufacturing FRP as well. And, in the future, the use of FRP and FRP products is expected to grow.